Scratches, dents or abraded areas: After years of reliable performance under all environmental conditions and temperatures, even a level sensor shows its age. RFID tags are now available for Vega sensors in the Pro series so that they can be identified at any time and anywhere despite a damaged or faded nameplate and traced back to the last serial number. RFID is not new and yet radio frequency identification is probably the most modern way of identifying sensors within industrial systems.

RFID tags contain a microchip for storing information. Because they are not only contactless readable with their writable chips, but also remain so for many years, even in wind and weather, rapid temperature changes or after years of exposure to sunlight, they are superior to other identification technologies. “Punched tags or even barcodes are ideally complemented by this, especially for outdoor installations,” Stefan Kaspar, Vega Product Manager, is also convinced. Whether in an extensive chemical park or in the oil and gas industry: “With an RFID tag, our sensors can be reliably traced even after years of intensive field use.”

Universal standard for sensor identification

The sensor identification is not only based on direct customer requirements, but also on the internationally valid IEC 61406 standard and the DDCC, a cross-manufacturer association of plant operators, service providers and manufacturers of machines and components for process automation that has been in existence for three years. Kaspar explains: “As a member of the Digital Data Chain Consortium, we are working together with many companies on an industry-wide standard for data exchange.” The consortium has a clear vision: “In future, access to and exchange of information between all participants should be made easier across the entire life cycle.” Regardless of which device and which manufacturer is behind a component: by simply scanning the QR code on the type plate with a normal photo app or by reading the RFID tag, users should be able to clearly identify their assets in future and access the associated documentation.

RFID tags for sensors as the first step towards a digital twin

The big picture is still a long way off, but the future has come a big step closer with the current ID solution. “No matter where you are in a system, in future you will be able to access a unique sensor identity with just one click,” says Kaspar, ”and from here directly to the digital twin, which contains all the important information about the device over its entire life cycle, from documentation to parameterization, repeat tests carried out and information for repair and recycling.” The RFID tag for sensors from Vega is therefore the first step on the way to the digital twin.

Individual measuring point identification for RFID tags for sensors

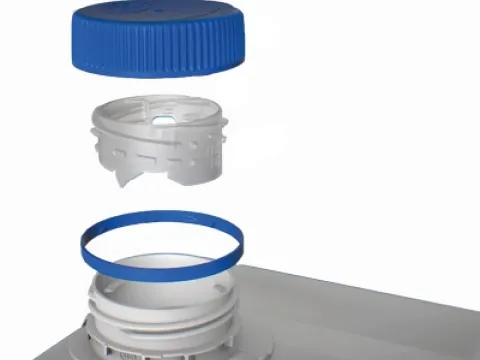

Alternatively, the RFID tag can also be labeled with an individual measuring point identification provided by the customer. The specific and clear identification helps to avoid operating errors and provides orientation. Kaspar is convinced: “From maintenance and service to servicing, this makes system operation more efficient and safer.” The RFID tags are initially available for the “Vegapuls 6X” radar level sensor and will subsequently be introduced for all other Pro devices.