New composting machines that can turn food waste into high-quality fertilizer in just 24 hours have been developed using technologies from Mitsubishi Electric. This solution responds to the global problem of waste, especially food waste, which accounts for about 30 percent of landfill waste. This technology enables Radisson Blu Scandinavia to process food waste from restaurants, room service and other food-related operations on a daily basis.

So in the hotel kitchen of Radisson Blu Scandinavia, several dozen kilograms of organic waste end up in a machine gleaming with brushed steel. The hermetic lid closes silently. The next evening, the same machine produces several kilograms of high-quality, nutritious fertilizer. Thus ends the era of food waste."What once took a year to complete can now be achieved in just 24 hours, significantly improving efficiency and sustainability. This solution represents a major step forward in waste management and environmental protection. By transforming food waste into valuable fertiliser, Mitsubishi Electric, and Solserv AB, bio solutions provider, are contributing to a more sustainable and circular economy, addressing both waste reduction and soil enrichment challenges", explains Maria Wendt, Marketing Communication Manager at Mitsubishi Electric Scandinavia.

Reduced methane emissions and less waste to landfills

These composters help reduce methane emissions, a major contributor to climate change, by diverting organic waste from landfills. Landfills are the third largest source of methane emissions, and composting helps mitigate this problem. The composters can process large amounts of organic waste, ranging from five kilograms to 500 tons per day, significantly reducing the amount of waste sent to landfills. The technology can turn food waste into nutrient-rich compost in only 24 hours, significantly speeding up the composting process compared to traditional methods. The resulting compost enriches the soil with nutrients and organic matter, promoting sustainable agriculture and reducing the need for chemical fertilizers.

Water conservation and energy efficiency

Electric composters help conserve water by retaining moisture within the composting system, which is especially beneficial in water-scarce regions. These composters allow continuous composting regardless of weather conditions, ensuring a consistent supply of compost throughout the year. The systems have odor control systems, making them suitable for urban areas and small spaces. While electric composters consume electricity, many models have energy-saving features to minimise power consumption. Additionally, using renewable energy sources to power these composters can reduce their environmental impact. The composters can process various types of organic waste, including biodegradable bags made from materials like Biodolomer, expanding their potential for waste reduction.

Radisson Blu Scandinavia invests in sustainability solution as a responsible company

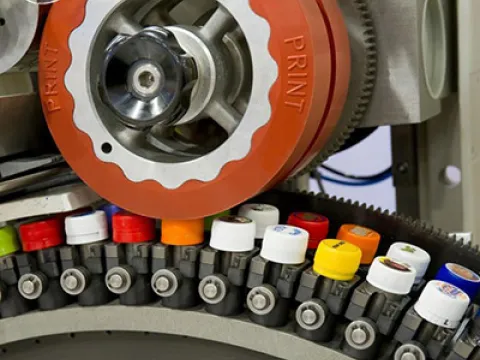

“Mitsubishi Electric's expertise has been crucial in developing precise and efficient composting processes. This collaboration ensures consistent quality and performance across different scales of operation. The partnership between Mitsubishi Electric and Solserv aligns with the United Nations' global goals, particularly in addressing the climate crisis. By converting organic waste into nutrient-rich compost efficiently, this technology promotes sustainability and significantly reduces waste”, sums up Patrik Johansson CEO at Solserv AB. Solserv composters, powered by Mitsubishi Electric automation solutions, are designed for various capacities and settings. Thanks to this versatility of applications, they represent a significant step towards a healthier and more sustainable future for our world. „We’re truly proud and happy we can be a big part of sustainability with our Noot Nordik Kitchen. We invested in this solution primarily because of sustainability and the work of responsible business. We also discovered that we reduced our food cost with waste management”, summarises Daniel Rodriguez, Food & Beverage Manager at Radisson Blu Scandinavia.

With this solution, Mitsubishi Electric is taking a major step forward in waste management and environmental protection. By turning food waste into valuable fertilizer, Mitsubishi Electric and Solserv are contributing to a more sustainable and circular economy, addressing both the challenges of waste reduction and soil enrichment.