Emerson will demonstrate how it’s transforming the future of factory automation through its proven Floor to Cloud approach and comprehensive portfolio at Hannover Messe in Hannover, Germany, on March 31 to April 4, 2025. Visitors to the Emerson booth will learn how companies of any size can drive sustainable growth, maximize performance quality and unleash workforce productivity for immediate and long-term success. Located in the Automation, Motion & Drives area, will feature immersive demonstrations and displays. This interactive hub will showcase how products from Asco, Aventics, Branson, Movicon, Pacedge and Pacsystems brands combine to form intelligent solutions that transform operations across the factory floor and deliver ongoing value. Scheduled presentations from Emerson experts in the Innovation Theater give visitors the opportunity to solve complex industry challenges and pathways to achieve a wide range of goals. Topics include driving sustainable growth, energy savings and efficiency, and proportional pressure control in robotic applications, as well as real customer success stories.

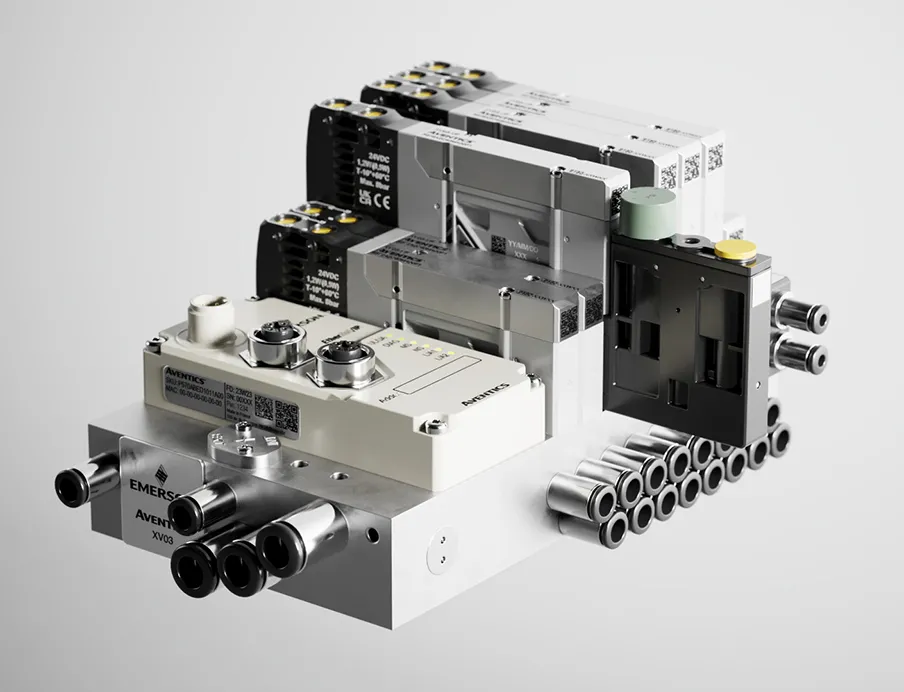

Pneumatic valves for greater reach and flexibility at higher flow rates

Next-generation Aventics Series XV pneumatic valves offer greater range and flexibility with higher flow rates to give original equipment manufacturers greater design flexibility and scalability when engineering handling systems or automation solutions. Designed with interoperability in mind, the new Series XV valves include a broader range of configurations and use proven core valve Aventics technology. Providing higher flow rates in a compact valve package, Series XV valves enable more efficient and flexible pneumatic system performance while offering products customized for specific markets, including factory automation, automotive and tire, food and packaging applications. Series XV valves include the "XV03", providing flow volumes up to 350 liters NL/min, and the "XV05", which can provide up to 1000 NL/min.

Flow sensors reduce compressed air consumption and improve energy efficiency

Aventics Series AF2 Flow Sensors have helped plants around the world successfully reduce compressed air consumption and improve energy efficiency. By monitoring air consumption in pneumatic systems, AF2 sensors enable rapid intervention if leaks occur, helping optimize energy consumption, reach net-zero targets, prevent machine downtime and reduce costs. Emerson also offers a high-flow model of this advanced sensor that propels compressed air monitoring beyond individual machines to benefit larger air lines and systems. This expanded capability allows users to easily optimize energy consumption across an entire packaging facility and improve overall plant sustainability.

Energy manager solution cuts energy costs and CO2 emissions by up to 30 percent

Designed to help manufacturers cut energy costs and carbon emissions by up to 30 percent, the new Energy Manager solution from Emerson transforms energy challenges into opportunities. Machine tools are energy-intensive, even when idling. This plug-and-play system offers real-time electricity monitoring to identify and minimize waste, optimizing energy use and boosting operational efficiency. With quick setup and intuitive operation, the Energy Manager provides detailed insights into energy consumption and operating costs, allowing plant managers to reduce idle consumption and peak loads. This application can also be used in conjunction with the Compressed Air Manager solution, offering a scalable, comprehensive view of energy and utility consumption.

Software platform supports decisions related to sustainability and efficiency strategies

Today’s manufacturing facilities require modern automation technology that can readily adapt and meet changing production and operational requirements. Success increasingly depends on advanced Scada solutions that seamlessly integrate diverse systems and assets, often over wide geographic areas, while maintaining robust cybersecurity. The Movicon industrial software platform delivers the next-generation of Scada/HMI connectivity and operability through modular, scalable and secure interfaces. The innovative suite of tools includes “Movicon Pro.Lean”, which harvests real-time production and performance data that can be used to reduce waste and increase profitability, and “Movicon Pro.Energy”, which measures energy consumption and can guide decisions around sustainability and efficiency strategies.

Programmable automation control systems

Industrial operations today need a flexible, scalable and affordable approach to modernization. Pacsystems controllers add a new dimension to industrial control and automation, allowing production optimization and monitoring capabilities in the widest range of process and discrete industrial environments. These automation control solutions bring control intelligence with a real-world approach to identify and predict impending failures, enable proactive maintenance, boost cyber security and customize data acquisition and analytics. So businesses can minimize downtime and handle market changes with agility. Core Emerson automation control innovations include the Pacsystems “RX3i CPL410” and “CPE330” controllers, which offer extensive flexibility for a range of applications, as well as the “RSTi EP I/O”, which combines powerful controller technology in a modular, compact form factor with a full range of slice I/O to maximize productivity.

Edge devices combine deterministic controls with safe, non-deterministic controls for analysis and machine learning algorithms

Emerson edge devices combine the best deterministic controllers on the market with secure, nondeterministic controllers for analytics and machine learning algorithms to proactively optimize business outcomes. These rugged devices are designed for remote industrial areas and equipped with our vendor-agnostic Pacedge software to safely run nondeterministic applications. This reduces latency and meets all application performance requirements. You will find Emerson at the Hannover Messe 2025 in hall 11, booth C30.