Photovoltaic systems on the roofs of industrial plants are no longer a rarity. High energy prices, as well as purchase limits and unstable networks in some countries and regions, make it lucrative to gain a degree of independence from the electricity market. Especially as the use of renewable energies also contributes to sustainability goals. At the same time, there is still a lot of untapped potential in the efficient use of energy. Together with its partner Inesco, Wittmann is helping injection molding companies to exploit this potential. The key is the use of direct current as a direct energy source.

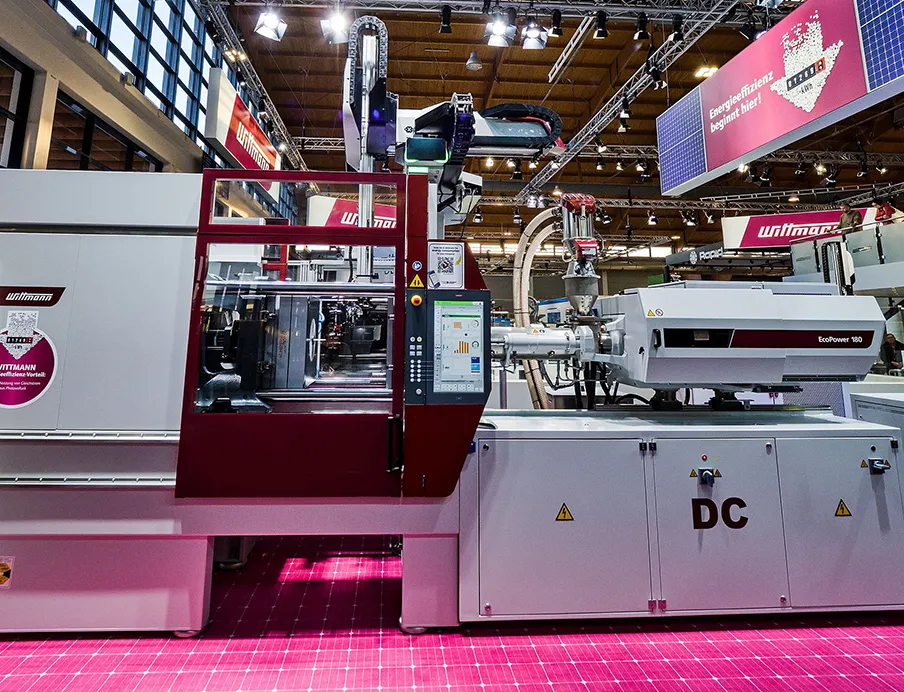

In 2022, at the K trade fair in Düsseldorf, Wittmann presented an injection molding production cell as a concept study in which electronic components are manufactured from flame-retardant polyamide. This was equipped with solar cells. The injection molding machine and robot are operated directly with solar energy via a DC voltage intermediate circuit. Only one year later, at the Fakuma 2023, Wittmann again presented a production cell that is operated directly with DC power from solar energy, this time as a production-ready solution including solar power storage. In the meantime, Wittmann has found a partner for the industrialization and marketing of DC injection molding technology. For more than ten years, Inesco has been working on the question of how renewable energies can be used sensibly and stored efficiently on a large scale. In the meantime, the first DC-capable injection molding machines have been sold.

Direct current brings security of supply into focus

Like other renewable energies, solar energy is direct current (DC). However, the general power supply is alternating current (AC). Inverters are used to make use of alternative energies. For transport and distribution, direct current is converted into alternating current and then partially converted back into direct current at the energy consumer. This is because many consumers work with direct current. Above all, these are frequency converters for stepless speed control of electric motor systems. This is because electric motors account for 70 percent of power consumption in industrial environments. Other examples of DC consumers include computers, televisions, LED lamps and electric vehicles. As a result, both in industrial production and in our daily lives, DC is constantly being converted into AC and back again. Some of the energy is lost with each conversion. The loss per conversion step is two to four percent.

DC grids promote climate neutrality

In addition to saving energy and the associated reduction in the CO2 footprint, there are other motivating factors to consider the possibilities of DC technology. It is primarily about security of supply. The increasing electricity consumption due to, among other things, electric cars and heat pumps, as well as the advancing electrification of industrial production, are increasingly putting a strain on the existing power grid. The expansion often lags behind, especially since the rapidly increasing feed-in of solar power is putting additional strain on the grids and making them more unstable.

Even in countries with a very good power supply, such as Germany or Austria, experts fear that there could be more grid failures or consumption restrictions in the future. Direct current grids could become an important building block for security of supply and climate neutrality. One contributing factor is that direct current can be easily stored in batteries, making it possible to efficiently cover expensive power peaks. Another argument is the greater resource efficiency in the expansion of the power grids. With the technologies available today, three-conductor DC grids require significantly less copper as a conductor material than five-conductor AC grids, and also fewer electronic components. For example, rectifiers in the devices are no longer needed.

Sodium salt battery maintains constant power

What exactly does the direct use of solar energy look like in an injection molding company? The Wittmann solution is based on three components: a Wittmann injection molding machine or production cell modified for DC technology, the “DConnect” DC power network from Inesco, and a Sodistore Max sodium salt battery. The battery was developed specifically for sustainable use in industrial companies.

“DConnect” forms the backbone of the DC power supply in the factory. It is a self-regulating DC microgrid into which DC producers and DC consumers can be easily integrated and connected. ‘DConnect’ does not require an external controller and does not need an internet connection. This means that the system is well protected against cybercrime.

Sodium-ion batteries achieve the same energy density as lithium batteries

The task of the DC-coupled storage battery is to ensure a constant voltage. This must also work even if different consumers are supplied and the electrical power provided is subject to fluctuations. Inesco offers sodium-salt-based solar storage batteries in various sizes with storage capacities of up to 500 kilowatts. Sodium-ion batteries achieve the same energy density and volume as conventional lithium batteries (LFP), but can be charged and discharged at much higher rates. The sodium-ion battery is significantly more environmentally friendly and also safer than conventional lithium batteries. It contains no harmful materials and can be fully recycled at the end of its service life. In addition, it does not require air conditioning and can be operated both indoors at higher temperatures up to 55 degrees Celsius and outdoors at very low temperatures down to minus 20 degrees Celsius.

For integration into the “DConnect” microgrid, Wittmann is initially offering injection molding machines from its Ecopower series and WX linear robots in a DC version. Other machine models and peripheral appliances are continuously being developed for integration into DC power grids. For example, Wittmann presented DC temperature controllers at its Competence Days in June 2020. To ensure safe operation of these components, the connection technology also had to be adapted. The Harting Technology Group developed a prototype for an electrically lockable connector specifically for this application. During operation, this protects both the system and the employees from unintentional disconnection and the associated electric arcs. The integrated signal display shows at all times whether voltage is present at the connector or not.

Kinetic energy recovery system for converting braking energy into electrical energy

The all-electric Ecopower machines with highly dynamic servo motors for driving the main movements are particularly suitable for use on a DC power supply. They are equipped with the patented Kinetic Energy Recovery System “KERS”, which converts kinetic energy into electrical energy during braking. In conventional AC operation, this energy can only be used within the machine itself, for example for the barrel heater. When integrated into a DC network, the recovered energy can also be fed back into the DC network to be made available to other consumers or stored in the battery.

The DC version of the Wittmann robot, which is powered directly from the DC bus of the Ecopower machine, also feeds excess energy back into the DC bus during braking. The production cell with an “Ecopower B8X 180/750+” injection molding machine, which was shown at the last trade fairs, produced with the installed salt storage capacity of 45 kilowatt hours for the entire eight hours of the trade fair day without interruption and without having to switch to the AC grid in the meantime.

Energy consumption drops by up to 15 percent with direct current

The first practical tests show that by reducing conversion losses alone, the energy consumption of a production cell supplied directly with DC drops by up to 15 percent. In this context, the establishment of DC networks is not a matter of either/or. Rather, DC grids will be established in more and more areas in parallel with the existing AC supply. If, for example, on cloudy days with less solar radiation, the battery storage should ever be exhausted, the system developed by Wittmann together with Inesco automatically switches to AC supply. The transition is not noticeable in production, the machine is continuously supplied with constant power.

It is likely that AC and DC networks will continue to coexist for a long time. This offers the advantage that it is possible to decide individually for each application which power supply offers the greatest overall efficiency.

Technical challenges of direct current technology have been solved

How quickly will DC become established in the injection molding industry? This question is not easy to answer, as it depends on many factors. The first step is to communicate the possibilities and advantages of DC technology more broadly, to find even more reference applications and to exchange experiences across industries more intensively.

The technical challenges have certainly been overcome. Solutions, components and protective mechanisms suitable for industrial use are available. Above all, however, a change in thinking is needed. DC technologies must be taken into consideration by plant planners, architects, electricians and energy consultants from the outset so that they can be evaluated when new investments are made.

ROI may be measured in seconds

Existing photovoltaic systems can be retrofitted for direct use of DC energy. However, replacing all inverters with DC-DC converters is a very expensive undertaking. The quickest way to achieve a return on investment is to set up and operate a DC microgrid when installing a new DC-coupled photovoltaic system. This allows the energy and load management to be designed in the best possible way from the outset. It is also recommended that not only the injection molding production cells, but also the peripherals and parts of the infrastructure, such as the compressed air supply, lighting and air conditioning, be integrated into the DC network.

However, the greatest influence on ROI is the stability of the power supply at the respective location. If there are regular interruptions to the power supply and limitations on the power provided, a DC microgrid with DC-coupled battery storage will pay for itself particularly quickly. For very critical components, investing in a DC power supply can pay for itself in the event of a blackout lasting just a few seconds.

Authors:

Mario Bruckner, Area Sales Manager, Wittmann Battenfeld

Max Ursin, Head of Development and Projects, Inesco