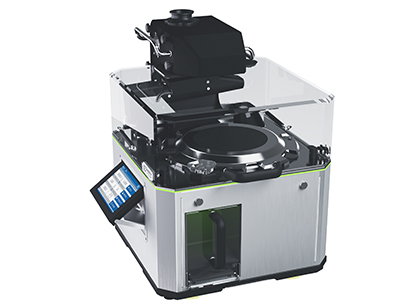

Testing tablets, even under containment conditions, is what the new "Checkmaster CM-X" from Fette Compacting does. Customers can see the tablet tester in action for the first time at Powtech 2023 in Nuremberg. In order to keep tablet production precisely under control, the device tests tablets randomly and under containment conditions of level OEB4 in interaction with the "F10i", "F20i" and "F30i" tablet presses of the new i-Series.

The "Checkmaster CM-X" analyzes the tablets produced for the parameters weight, size, thickness and breaking strength or hardness. The equipment thus complements the range of existing tablet testers. The ergonomic human-machine interface (HMI) of the new i-Series makes the system easy to operate while minimizing the risk of errors by eliminating manual data entry. "Operating the ,Checkmaster CM-X' via the HMI terminal of the tablet presses in our new i-Series results in complete data exchange between the tablet tester and the tablet press," explains Axel Schroeter, Senior Product Manager.

The new tablet tester includes the Smart-Feed, Clean-Feed and Vibra-Fix features as standard equipment: Behind the Smart-Feed term is a new separation system with a progressively controlled chute and automatic tilt adjustment.This ensures that only one tablet falls into the test device at a time.The Clean-Feed function significantly reduces tablet dust in the Checkmaster. Shielding from the negative pressure of the tablet press during sampling and measurement is automatic. Vibra-Fix supports length alignment of the test tablets by precisely positioning and stabilizing them in the device during testing for breaking strength and hardness. In addition, customers can order the auto-alignment function, which allows the device to adjust itself to the surface. This equipment is particularly worthwhile for uneven ground or if the machine is moved frequently. In addition, an OZB unit is available for tablets with a special shape. IQ/OQ documentation is also available.

Fette Compacting developed the equipment together with its long-term partner Kraemer Elektronik and tested it based on production scenarios. "We are pleased about the good cooperation with Kraemer Elektronik. In the development of the 'Checkmaster CM-X', we were able to combine our expertise and thus offer our customers convenient and at the same time safe handling in the field of containment applications," emphasizes Lars Plüschau, Vice President Global Sales at Fette Compacting.