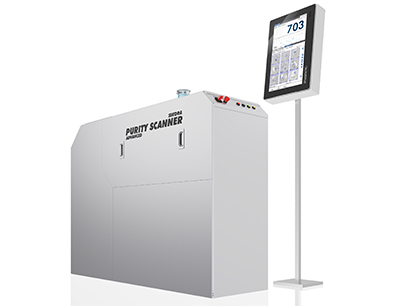

At Fakuma from October 17 to 21, 2023 in Friedrichshafen, Sikora will be presenting solutions for quality control in the pipe and hose and plastics industries. The trade show appearance is fully in line with the motto "Ideas, Passion, Future", which the company has developed on the occasion of its 50th anniversary. The modularly developed "Purity Scanner Advanced" system demonstrates how plastic material can be reliably sorted. In addition to optical 25-micrometer high-resolution cameras that detect black specks and discolorations, an X-ray camera ensures the detection of metallic contaminations. Depending on the material and requirements, the customer decides how many and which camera types are used. Common systems on the market have a maximum of two optical cameras. By using a third camera in the Sikora system, a significantly higher detection rate is achieved, so that more contaminants are detected. The interaction of reliable detection and intelligent sorting ensures the highest material quality. At the same time, production processes are optimized, contributing to cost-efficient and sustainable production.

At the Sikora booth, visitors can have small quantities of crystalline and amorphous granules, flakes or test plates automatically inspected and analyzed for contamination using the "Purity Concept V" inspection and analysis system.The system is suitable for reproducible laboratory applications and detects black and colored contaminants from a size of 50 micrometers as well as discolorations.Analysis takes less than a minute, including a test certificate and HSV color chart of the detected color deviations.The system thus contributes to increased product and quality safety.Visitors can see the system's performance live at the booth and are invited to bring samples to be tested free of charge.

In the extrusion sector, Sikora will present the "Centerwave 6000/250" for measuring pipes in the diameter range from 32 to 250 millimeters during production based on millimeter wave technology.All dimensions of the pipe, such as the diameter and wall thickness, are determined and visualized in real time over 360 degrees of the pipe circumference.The measurement data obtained enables automatic control of the minimum wall thickness, taking into account the standard deviation of the extrusion line.This allows potential savings to be exploited to the maximum. In the line, the system enables seamless, reliable quality control as well as automatic regulation. The model is characterized by its simple operation. At the push of a button, the operator immediately obtains continuous and precise measured values, without presetting the product parameters, without the influence of a coupling medium, and without any calibration. The Centerwave on display is just one model from a comprehensive product family offered by Sikora for measuring different product diameters from 32 to 3,200 millimeters.

For more than 30 years, the machine manufacturer from Bremen has been offering X-ray technologies for quality control and enables manufacturers to reliably check the inline quality of stranded products. The X-ray measuring system "X-Ray 6000 Pro" in combination with the processor system "Ecocontrol 6000" demonstrates how different layers of tubes and hoses can be reliably measured during extrusion.On the 22-inch monitor, the measured values are displayed both numerically and graphically as trend and statistical data.By default, the wall thickness is displayed at eight measuring points.In addition, an intelligent physical evaluation model determines the minimum wall thickness, i.e. the available value, which optimally supports the user in controlling the process.The physical model also allows the wall thickness to be visualized over the entire circumference of the tube or hose at any point.The user chooses how many points and at which position the values are to be displayed.Furthermore, the processor system is used for automatic control of the line speed or extruder rpm.It thus guarantees compliance with the given specifications as well as maximum performance for maximum process optimization and productivity. The "X-Ray 6000 Pro" can be used for product diameters from 0.65 to 270 millimeters.

For products where a single-layer measurement is required, the manufacturer is presenting the "X-Ray 6000 Pure" to Fakuma visitors. Also using X-ray technology, the device measures single-layer products as well as the total wall thickness of multilayer products and covers product diameters from six to 110 millimeters with two models.The measured values are visualized on a 15-inch display, and automatic control to minimum wall thickness is also possible if required.Ensuring quality while saving material leads to a significant increase in productivity and also helps to save CO2 and thus protect the environment.Sikora will be exhibiting at Fakuma 2023 at booth A6-6110.