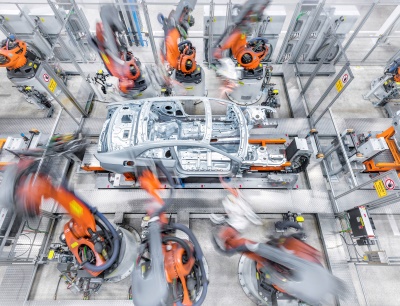

In the second quarter of 2021, Kuka was commissioned with the planning, delivery and integration into several body assembly lines for the underbody of two new vehicle models in the mid-size and luxury classes. With this order in the mid-single-digit million euro range, Audi is once again relying on Kuka's technological expertise.

For the sub-area of the underbody, Kuka is responsible for integration and partial cycle time reduction in two fully automated body shop lines. Here, around 200 Kuka robots handle process technologies such as resistance spot welding and adhesive bonding. "Our many years of experience in designing flexible and efficient manufacturing processes make us a reliable partner to the automotive industry,” said Gerald Mies, CEO Kuka Systems. “We are pleased about the trust placed in our technologies.”